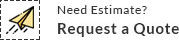

3D Robotic Laser Cutting Machine

3450000 INR/Unit

Product Details:

- Laser Type Fiber Laser

- Material Metal

- Cutting Thickness 10 Millimeter (mm)

- CNC Or Not CNC

- Computerized Yes

- Automatic Grade Automatic

- Cooling Mode Water Cooling

- Click to View more

X

3D Robotic Laser Cutting Machine Price And Quantity

- 1 Unit

- 2300000.00 - 5000000.00 INR/Unit

- 3450000 INR/Unit

3D Robotic Laser Cutting Machine Product Specifications

- Automatic

- 10 Millimeter (mm)

- 2 year

- Yes

- CNC

- Metal

- High Performance, Lower Energy Consumption, Touch Screen, Simple Control, ECO Friendly, Low Noise, High Efficiency

- Fiber Laser

- Water Cooling

- Other

3D Robotic Laser Cutting Machine Trade Information

- Pune

- Cash in Advance (CID)

- 2 Unit Per Year

- 30 Days

- Yes

- Free samples are available

- standard packing

- Asia

- All India

Product Description

3D Robotic Laser Cutting Machine

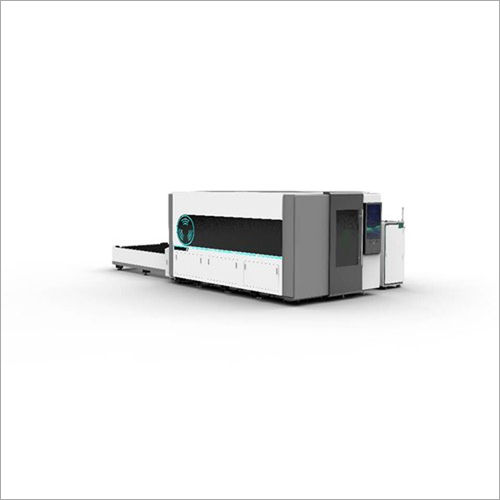

We offer a power range from 180 Watt to 850 watts with Articulated arm beam delivery to be able to do any kind of 3D non-metal cutting.

Features

- High Speeds of cutting due to the high power delivered at the process end

- Sensor with proper focusing head to keep the focus constant for high-quality cutting

- Light pay load at ROBOT giving flexible movement and high speed

- Circles of small die possible and they are circles or ellipse ( In other solutions you cannot get perfect circles)

- Constant laser power throughout the life of the machine. No need to send laser for refilling. Long life lasers (life of 25+ Year)

- Very low ownership cost

- Beam delivered through enclosed path, Safe and secure

- Standard low-cost ROBOTS can be easily managed by Local Robot programmers

- 1-year full warranty and local support on the system

- Complete training in ITALY on the complete system. Award-winning innovation from ABB

- ABB global application support

Smart Automation and Simple Control

Equipped with automatic grade operation and CNC capabilities, our 3D Robotic Laser Cutting Machine simplifies complex metal cutting processes. The intuitive touch screen interface allows operators to control the entire workflow effortlessly, reducing manual interventions and errors. Advanced programming and automation make it suitable for demanding industrial environments, maximizing productivity through quick, repeatable, and precise cuts every time.

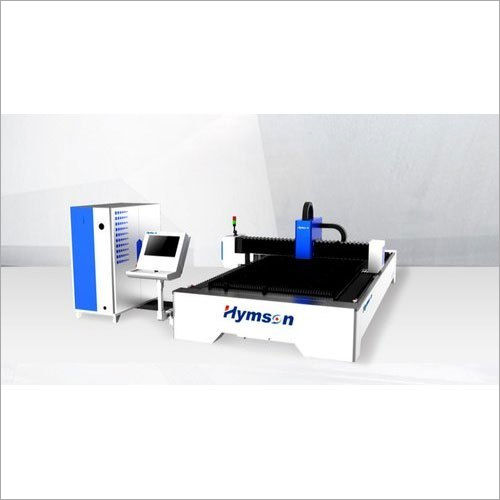

Eco-Friendly, High-Efficiency Metal Cutting

Designed for environmental responsibility and energy savings, this machine boasts lower energy consumption and minimal noise levels. The integrated water cooling system maintains optimal performance, protecting components and ensuring long service life. These features not only lower operational costs but also create a cleaner, safer workspace for your team, setting a new standard in metal fabrication technology.

FAQs of 3D Robotic Laser Cutting Machine:

Q: How does the automatic grade feature improve the laser cutting process?

A: The automatic grade functionality ensures the machine operates with minimal manual intervention, enabling smooth, consistent, and highly accurate cutting. This results in faster job completion, reduced labor requirements, and increased precision in producing intricate metal parts.Q: What materials and thicknesses can this fiber laser cutting machine handle?

A: This machine is specifically designed for metal processing and can efficiently cut materials up to 10 millimeters thick. Its fiber laser technology ensures clean and precise edges, making it suitable for various industrial applications.Q: When is water cooling necessary for laser cutting machines?

A: Water cooling is essential when operating high-performance fiber laser machines to dissipate heat generated during extended or intensive cutting sessions. This system maintains temperature stability, safeguards machine components, and maintains cutting quality.Q: Where can this 3D robotic laser cutting machine be installed?

A: The machine is suitable for installation in industrial environments, workshops, and manufacturing facilities requiring efficient and automated metal cutting. Its low noise and eco-friendly design make it adaptable to both small and large-scale production floors.Q: What is the main process behind CNC robotic laser cutting?

A: The process begins with computer-aided design (CAD) input, which the CNC system translates into precise movement paths. The robotic arm positions the laser head, which then cuts the metal along programmed contours, ensuring accuracy and repeatability throughout the job.Q: How does an operator control and monitor this machine?

A: Operators interact using the integrated touch screen control panel, which provides a straightforward interface for programming, monitoring, and adjusting parameters. Real-time feedback and system diagnostics ensure safe and reliable operation.Q: What are the key benefits of using your 3D robotic laser cutter?

A: Key benefits include high efficiency, reduced energy consumption, low operational noise, and superior cutting accuracy. The machines automation and simple control system allow for rapid production cycles, lower operating costs, and enhanced workplace eco-friendliness.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email