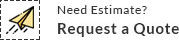

3D 5 Axis Laser Cutting Machine

2300000.00 INR/Unit

Product Details:

- Product Type CNC fiber laser metal cutting machine

- Laser Type Fiber Laser

- Material Metal

- Cutting Thickness 20 Millimeter (mm)

- CNC Or Not CNC

- Computerized Yes

- Automatic Grade Automatic

- Click to View more

X

3D 5 Axis Laser Cutting Machine Price And Quantity

- 2300000.00 INR/Unit

- 1 Unit

3D 5 Axis Laser Cutting Machine Product Specifications

- CNC

- Metal

- Cypcut

- 2 year

- Yes

- Other

- Automatic

- 20 Millimeter (mm)

- Fiber Laser

- DXF

- CNC fiber laser metal cutting machine

3D 5 Axis Laser Cutting Machine Trade Information

- Pune

- Cash in Advance (CID)

- 5 Unit Per Year

- 25 Days

- Yes

- Contact us for information regarding our sample policy

- Standard Packing

- Asia

- All India

Product Description

3D 5 Axis Laser Cutting Machine

3D, 5 axes Laser Metal Cutting Machine for industrial applications. Extreme flexibility to make your 3D parts.

3D 5 Axis Laser Cutting Machine is a fully automated machining unit that can be used in various industries to make precision cuts up to the thickness of 20 millimeters. It is provided with a CNC control that makes it easier for a single user to set operational parameters. The laser gun of this cutting unit is capable to make cuts in multiple directions. Customers can get 3D 5 Axis Laser Cutting Machine at a reasonable and low price range.

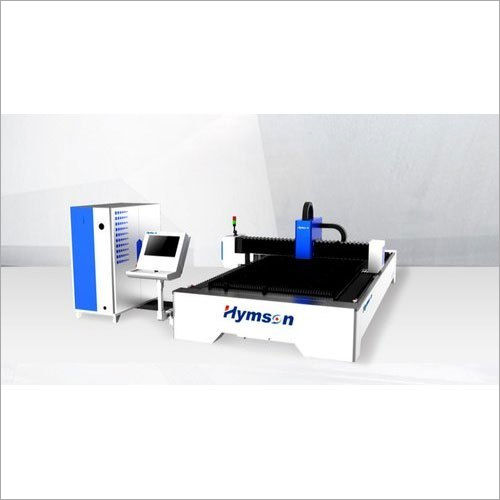

Precision and Versatility in Metal Cutting

This 3D 5 Axis Laser Cutting Machine stands out for its advanced CNC technology and versatile cutting capabilities. Supporting up to 20 mm of metal thickness and compatible with DXF files, it allows manufacturers to realize intricate designs with excellent accuracy. The automatic grade and fiber laser technology add efficiency and high-quality results for various industrial needs.

Seamless Integration with Modern Production

Equipped with Cypcut control software, this machine streamlines the cutting process from graphics import to the final product. Its compatibility with DXF files simplifies workflow for engineers and designers, making it a valuable addition to manufacturing environments that demand precision and automation.

FAQs of 3D 5 Axis Laser Cutting Machine:

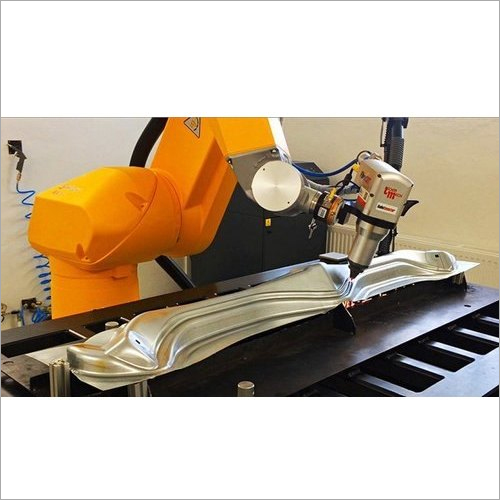

Q: How does the 3D 5 Axis Laser Cutting Machine operate for complex metal fabrication?

A: The machine uses a fiber laser guided by an advanced CNC system with five axes, allowing it to cut metal in intricate shapes and at varying angles. The process is managed through Cypcut software, which provides precise control and automates cutting sequences for maximum efficiency.Q: What materials and thicknesses can this laser cutting machine handle?

A: Designed specifically for metal processing, the machine can cut materials up to 20 millimeters thick. Its robust build and powerful laser allow it to work effectively with a wide range of metals, accommodating different industrial needs.Q: When should I consider using a 5-axis laser cutting machine over traditional 2D or 3-axis systems?

A: A 5-axis machine is ideal when your projects require complex geometries, angled cuts, or multi-surface processing that simpler 2D or 3-axis systems cannot achieve. It offers greater flexibility and precision for advanced manufacturing tasks.Q: Where can this machine be installed and operated?

A: The machine is suitable for installation in manufacturing units, fabrication shops, and industrial environments across India or internationally. As an automatic system, it requires a stable workspace with reliable power and safety provisions.Q: What is the process for importing and executing cutting designs?

A: Designs are created in compatible CAD software and saved in DXF format. These files are imported into the Cypcut control software, where you can set cutting parameters and initiate automated production, ensuring a streamlined workflow from concept to cut part.Q: How is reliability ensured and what warranty is provided?

A: The machine comes with a comprehensive 2-year warranty, covering manufacturing defects and providing access to technical support. This ensures long-term reliability and peace of mind for users.Q: What are the key benefits of choosing this 3D 5 Axis CNC Laser Cutting Machine?

A: Benefits include high-precision cutting, adaptability to complex designs, automated operation for increased productivity, compatibility with widely-used file formats like DXF, and robust after-sales support as provided by a reputable Indian exporter and manufacturer.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email